With a history of quality and innovation and a reputation…

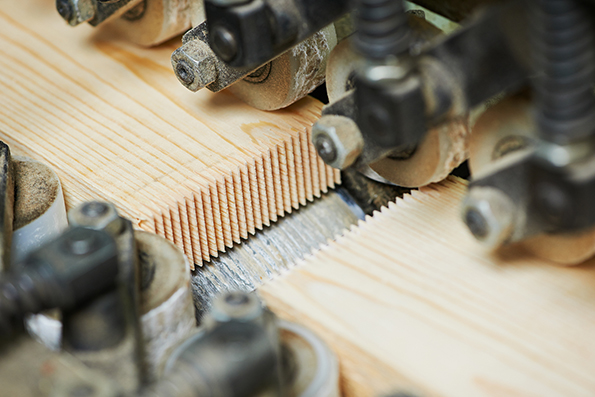

Current Sensors in woodworking machines run vacuum fans to clear sawdust and debris

For clean finishing, accurate work and safer surfaces, woodworking equipment and factory installations use Airotronics Current Sensors. When the CS senses current to power on a cutting, joining, planing or finishing machine, the relay output turns on an integrated vacuum and fan system.

Shavings, chips and sawdust are cleared away as the work is done. In commercial applications, the Current Sensor is built into the control panel for cutting tools, saws, routers and more.

Shavings, chips and sawdust are cleared away as the work is done. In commercial applications, the Current Sensor is built into the control panel for cutting tools, saws, routers and more.

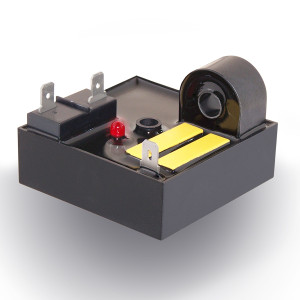

An on-board LED indicates sensed current through the toroid. When the current exceeds 1Amp, the relay turns on the fan, with a 1.5hp motor powered by 120VAC line voltage.

Also suitable for woodworking workshop DIY vacuums; look online for how-to articles.

CURRENT SENSOR with RELAY OUTPUT

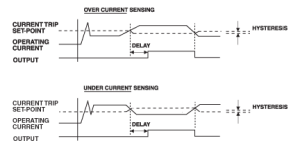

- Over-current or under-current sensing

- Toroidal sensor

- Current sensor can handle up to 20 amp loads

- Time delays up to 100 seconds

Relay Life Expectancy

Mechanical: Up to 10 million operations

Electrical: 100,000 operations at max. load

Airotronics CS is an over- or under-current sensing control. Toroidal sensing means no break in the power wiring.

Airotronics CS is an over- or under-current sensing control. Toroidal sensing means no break in the power wiring.

The combination of the over current LED, current adjustment, and percentage trip adjustment provides easy, accurate setting.

With innumerable options for our many standard products, we can create an Airotronics control specifically for your product, facility or application. For safety systems or efficiency updates, when you’re Putting Power to Work, build in reliability with Pelco Component Technologies.

With innumerable options for our many standard products, we can create an Airotronics control specifically for your product, facility or application. For safety systems or efficiency updates, when you’re Putting Power to Work, build in reliability with Pelco Component Technologies.